Interview with Xiao Jianfeng, Founder of Dongguan Xiaotanglang Cutting Tool Manufacturing Co., Ltd.

Li Wei, Editor-in-Chief of Cutting Tool World

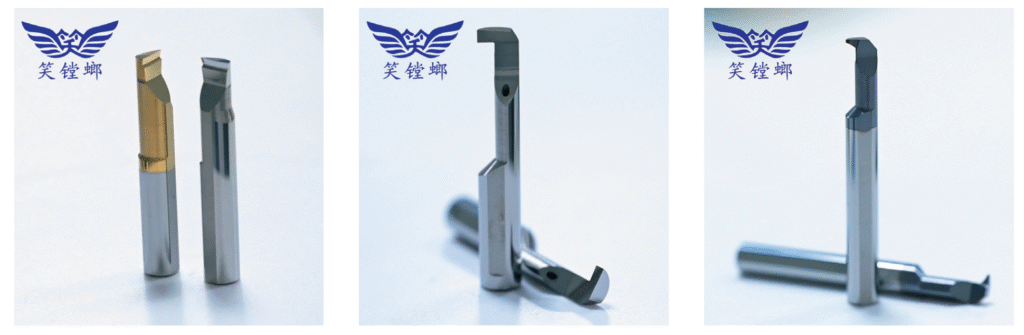

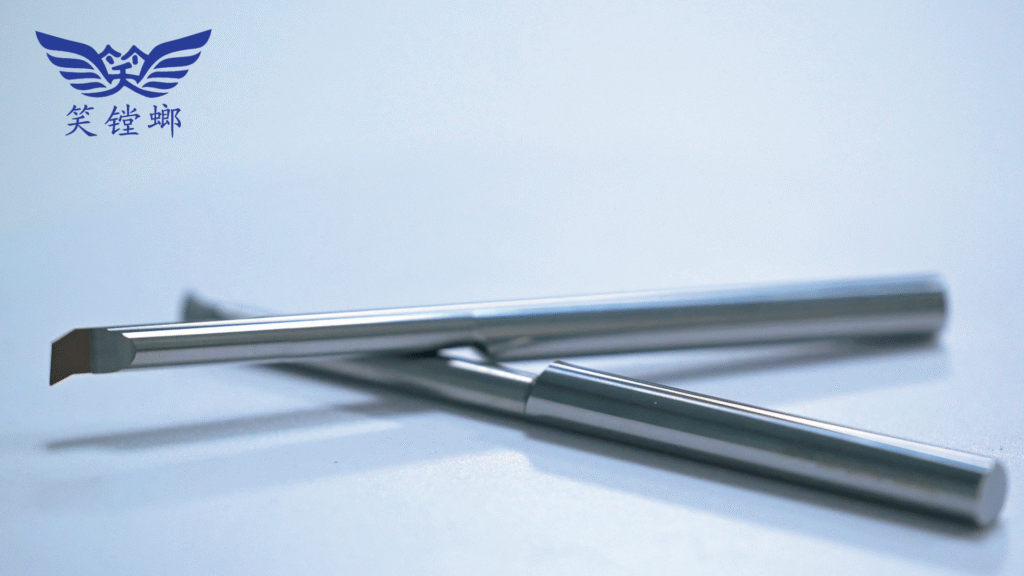

In the field of precision manufacturing, there is a type of tool that seems insignificant but is often overlooked, with very few tool companies truly mastering its production. This tool is the “small-diameter boring tool.”

Small-diameter boring tools may appear simple, but their manufacturing process is inherently complex, where every minute detail determines the success or failure of the tool. Achieving excellence in small-diameter boring tools is by no means an easy task. In this narrow and challenging niche, Dongguan Xiaotanglang Cutting Tool Manufacturing Co., Ltd. has dedicated over a decade to deepening its expertise, focusing exclusively on the production of small-diameter boring tools. Through meticulous refinement in materials, coatings, and processes, the company has accumulated technical advantages, maintaining steady progress amid industry involution and the wave of low-price competition.

In this exclusive interview, Li Wei from Cutting Tool World magazine visited Xiaotanglang for a face-to-face conversation with founder Xiao Jianfeng, exploring how the company utilizes “extreme focus” to break market prejudices and forge a path of survival and development characterized by being “small yet refined, specialized yet precise.”

From “Mantis” to “Boring Tool”: The Professional Insight Behind the Brand Name

Upon entering Xiaotanglang’s tidy and bright workshop, one can’t help but feel it’s completely different from a traditional tool manufacturing factory. The factory floor is spotless, with rows of clean production equipment neatly aligned. Carefully placed green plants add a refreshing touch to the workshop, and the open-office environment brings a sense of relaxation and comfort.

“Many people mistake it for ‘Mantis'(螳螂) at first glance, but actually, ours is the ‘gold'(钅) radical ‘boring'(镗), homophonic with ‘boring tool’,” Mr. Xiao first explained the easily “misunderstood” name “Xiaotanglang”. Mr. Xiao told us that small-diameter boring tools are used for hole machining in finishing processes. Their structure is somewhat similar to a mantis’s arm – hard, precise, and sharp. Hence, the name “Xiaotanglang” is both interesting and memorable.

The brand name itself reveals Mr. Xiao’s deep understanding of the product characteristics and his dedication to the field of small-diameter boring tools. However, Mr. Xiao also took some “detours” initially. When Xiaotanglang was first established, its product range included small-diameter boring tools, flat drills, and even milling cutters. The variety of products led to “jack of all trades, master of none,” consuming time and effort without achieving breakthroughs. Consequently, Mr. Xiao sought advice from Teacher Gao Rong from CMEC. Teacher Gao pointed out that among Xiaotanglang’s products, although the market size for small-diameter boring tools was not large, their high process threshold and clear demand presented an opportunity for differentiation. Guided by Teacher Gao’s advice, Mr. Xiao clarified the direction and began focusing deeply on the field of small-diameter boring tools from 2015 onwards.

“Specialized and Refined”: Building a Wide Moat on a Narrow Path

“Small-diameter boring tools may look simple, but they truly embody ‘details determine success or failure’,” Mr. Xiao said with a tone full of rigor when discussing the product. “The same tool can perform completely differently for different customers. Some prioritize tool life, others require superior surface finish, and some pursue efficiency. We must adjust the coating, passivation, and groove design based on the customer’s machine tool, material, cooling method, and even operating habits.” He emphasized that this is not a ‘one-size-fits-all’ business, but a transaction of ‘integrated solutions‘.

Mr. Xiao told us that Xiaotanglang does not serve end-users directly, but focuses primarily on distributors and agents. End-users are engaged solely for product testing. “This allows us to concentrate all our energy on production and technology, without diverting resources to business entertainment.” When asked about considering expanding the product range, Mr. Xiao stated firmly: “No. It’s not that other categories are bad, but our team, technology, and equipment are all built around small-diameter boring tools. Switching to another category would be like starting over. Human energy is finite. I believe achieving mastery in one product category is itself a success.”

With years of experience in the industry, Mr. Xiao has witnessed too many lessons of ‘greeding for more’: “Some companies started with small-diameter boring tools, saw that milling cutters for the 3C industry were profitable, and jumped on the bandwagon, only to end up failing at both. No matter how small the niche for small-diameter boring tools is, mastering it thoroughly creates barriers; no matter how large another sector is, distraction leads to failure.” It is this extreme focus and persistent dedication over ten years that has allowed Xiaotanglang to carve out its own blue ocean. Currently, Xiaotanglang not only possesses a comprehensive inventory system covering small-diameter boring tools in various structures and sizes, but can also quickly provide customized solutions for clients’ differentiated needs. “We don’t aim for ‘large and powerful‘, but rather ‘specialized and refined‘ — establishing brand recognition through specialization, so that when customers think of small-diameter boring tools, they think of Xiaotanglang first.”

Refinement in Technology: Calmly honing the process

Beyond “specialization” in the product domain, Xiaotanglang also pursues “refinement” in technology. The production base is located in Fenggang, away from the hustle and bustle of big cities. The tranquility and quiet here provide an environment conducive to focused R&D and production. “Without the need for excessive social engagements, we can calmly dedicate ourselves to refining our processes. This is crucial for manufacturing,” Mr. Xiao stated.

Resisting Involution: Navigating the Price War with ‘Reliability’

Facing low-price competition and internal competition within the industry, Mr. Xiao said such behavior is akin to shooting oneself in the foot. “We never participate in price wars. A difference of two or three yuan per tool might be sensitive to some customers, but it’s insignificant compared to the overall solution. Ultimately, customers pay for ‘reliability‘.” Because of this, Xiaotanglang persistently adheres to reasonable pricing and maintains sufficient profit margins, allowing them to calmly cope with cost pressures from rising raw material prices.

Looking to the future, Mr. Xiao said they will continue steadily, persisting with small-diameter boring tools and passing down the foundation of “specialized and refined.” In his view, as long as they continue to refine their products, they need never fear having no market.

Editor’s Postscript:

In today’s business world obsessed with “speed” and “scale,” Xiaotanglang stands as an example of “going against the grain.” With an almost stubborn focus, it demonstrates the value of “specialization” and the power of “refinement.” It shows us that the resilience of Chinese manufacturing exists not only in grand narratives and scale expansion, but is also embedded in the meticulous crafting of a single “industrial tooth.”